We could go with any kind of style starting with a wooden soap box derby car to a Sherman Tank. But it is best not to waste a lot of time by starting a project only to find out half way in that it either does not fit together well or you just plain don't like it. I can speak from experience on this one. I just got through untacking a bunch of welds on something that seemed like a good idea at the time. A simple and inexpensive way to test out our idea first is by modeling. It is fairly easy to build a scale model of the project using balsa wood, card stock, paper, plastic or whatever you have on hand. So where do we start? I am fortunate enough to have access to a cad cam computer program that allows for making precise drawings that can be scaled and used to accurately produce the component parts for the model. These drawings can be translated into a DXF file that can be read by a CNC controlled knife cutting table that I also happen to use in my business. Now you can make perfectly good models without aid of computerised equipment but it takes a lot more time and artistic ability. Since I have chosen the Jordan F1 car as a design then I must find out some dimensional information about the car. One source book I use for such information is entitled "Race and Rally Car Source Book" written by the late Allen Staniforth. Allen passed away this year. The book is footnoted as a guide to building or modifying a competition car. I have no real interest in racing rather I am interested in designs that make a car handle in a predictable and reliable manner. Allan has a writing style that can take a rather dull and boring subject like suspension travel and turn radius and mix it with his matter of fact humor and personal experience that gives a bit of heart and soul to the technical aspect of automotive design. For instance in describing the ratio between track and wheel base he states "It usually falls within the 1.4 to 1.7 bracket but an ideal figure is like that of the ideal woman: hard to find and even harder to define." The ratio of 1.62 is known as the 'Golden Section' considered by some to be the ideal proportion visually. The Jordan F1 911 has a proportion of 1.665. Close enough for me.

I will not bore you with all the details of how the dimensions were determined. Just suffice it to say that the only dimensions of the Jordan F1 that I knew for sure were the wheel base and the Track. Wheel base refers to the distance between centers of wheels lengthwise and Track is the width across from center of tires. The wheel base for the full size race car is 114.1 inches and the Track is 68.5 inches. I first scaled these dimensions down to a size that sounded about right for children from 6 to 12 years old. In other words it would be too big for small 6 year olds and a bit cramped for larger preteens. Then I sized it down to a 1/8 scale for the model. There is a Web Site called Jimbob Wans Scale conversion calculator that will convert any dimension to any scale you dial in. For the rest of the dimensions you just have to look at pictures and do some test sketching until you are pleased with the way it looks. Remember this is just for a model and at this point any changes are easy to make.

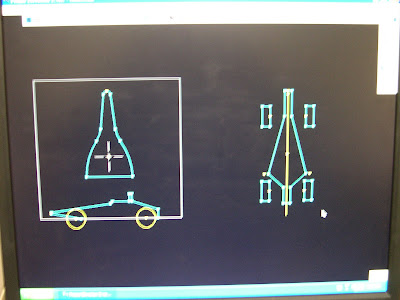

This is a picture of the parts that have been sketched in the cad system. The next step is to convert the drawings to a DXF file.

1958 Ferrari 246 Formula 1

1958 Ferrari 246 Formula 1

This is a Chicago Electric Easy Mig 100. You can buy it at Harbor Freight for about $150.00. I have owned one of these and for the money it worked fairly well. If the wire quits feeding then the fuse is probably blown. I sold it on E bay and got a step up.

This is a Chicago Electric Easy Mig 100. You can buy it at Harbor Freight for about $150.00. I have owned one of these and for the money it worked fairly well. If the wire quits feeding then the fuse is probably blown. I sold it on E bay and got a step up. This is my Hobart Model 140. It is a mid range priced model and currently sells at Northern Tools for under $500.00.

This is my Hobart Model 140. It is a mid range priced model and currently sells at Northern Tools for under $500.00.

Next you need to be aware of the tools that are required. I will make a list of what is needed and then give detailed suggestions on ways to go. As in most things there are many different ways to go about something. I do not profess to know the best way to do anything. There is good, better and best. I am aquainted with good and better. I was once introduced to best but he turned out to be an imposter. There is also "ain't no good" and unfortunately we will all run into him every once in a while. But the point is to learn to recognize him and run the other way. So here is how it works. There needs to be respect. Few among us know everything. My skills may appear elementary compared to yours. But if you will respect my less than perfect ways of doing things then I will refrain from making comments about your mother. But if there is any disrespect then whether or not your momma wears army boots will be the least of her worries. Fair enough?

Next you need to be aware of the tools that are required. I will make a list of what is needed and then give detailed suggestions on ways to go. As in most things there are many different ways to go about something. I do not profess to know the best way to do anything. There is good, better and best. I am aquainted with good and better. I was once introduced to best but he turned out to be an imposter. There is also "ain't no good" and unfortunately we will all run into him every once in a while. But the point is to learn to recognize him and run the other way. So here is how it works. There needs to be respect. Few among us know everything. My skills may appear elementary compared to yours. But if you will respect my less than perfect ways of doing things then I will refrain from making comments about your mother. But if there is any disrespect then whether or not your momma wears army boots will be the least of her worries. Fair enough?